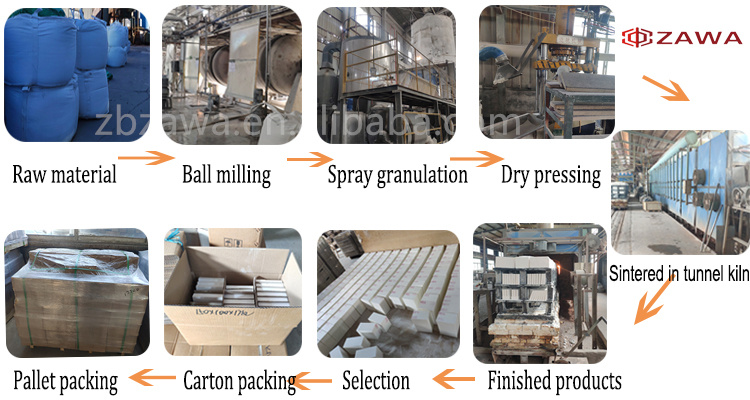

Generally speaking, the preparation process of wear-resistant 95 alumina ceramics tiles includes the following steps: preparation and treatment of powder, forming, sintering and post-processing of end products. The quality of each process will affect the performance of later ceramic products. The more important raw material for raw materials and processing alumina ceramics is Al2O3 powder. Its performance and content have a great influence on alumina ceramics. α- Al2O3 has compact crystal structure, high hardness, wear resistance, high temperature stability and good mechanical and electrical properties. so α- Al2O3 is usually the main and commonly used raw material for manufacturing alumina ceramics. α- Ceramic products with high Al203 content have high strength, high density and good wear resistance. Pre firing and pre firing of Al2O3 is one of the important links in alumina ceramic production. Industrial Al2O3 should be pre fired before billet making. Pre firing can also remove Na2O and other substances and improve the purity of raw materials. Different pre firing methods, different additives, different atmospheres and different pre firing quality. The pre firing quality is also related to the pre firing temperature.